Welcome everyone, and welcome to the very first project spotlight from Low Standard Society! Today, we’re diving headfirst into a truly special build: my 1983 Golf Mk1 GTI. This isn’t just any old car; it’s a genuine barn find that’s been waiting patiently for its second life, untouched for 22 years. Join me as we chronicle the journey from a dusty, forgotten classic to a meticulously restored and lightly modified icon.

The Resurrection: A Barn Find Awakening

The thrill of discovering a hidden gem is something every car enthusiast dreams of. For me, that dream came true when I stumbled upon this ’83 Mk1 GTI, dormant in a barn for over two decades. The moment we tried to awaken it for the first time was pure magic, filled with anticipation and the roar of a sleeping engine.

After its initial grumpy awakening, the next step was getting it home and taking a proper look at its raw, untouched state. The dust of decades told its own story, hinting at the journey ahead. The charm of a true barn find, still covered in history.

Hoisting the car up, it became clear that 22 years of slumber hadn’t been kind to the underbody. Rust, as expected on a car of this vintage, had definitely made itself at home, revealing the true scale of the restoration needed. This was the first real challenge that presented itself.

Rust Repair & Chassis Transformation: Battling the Elements

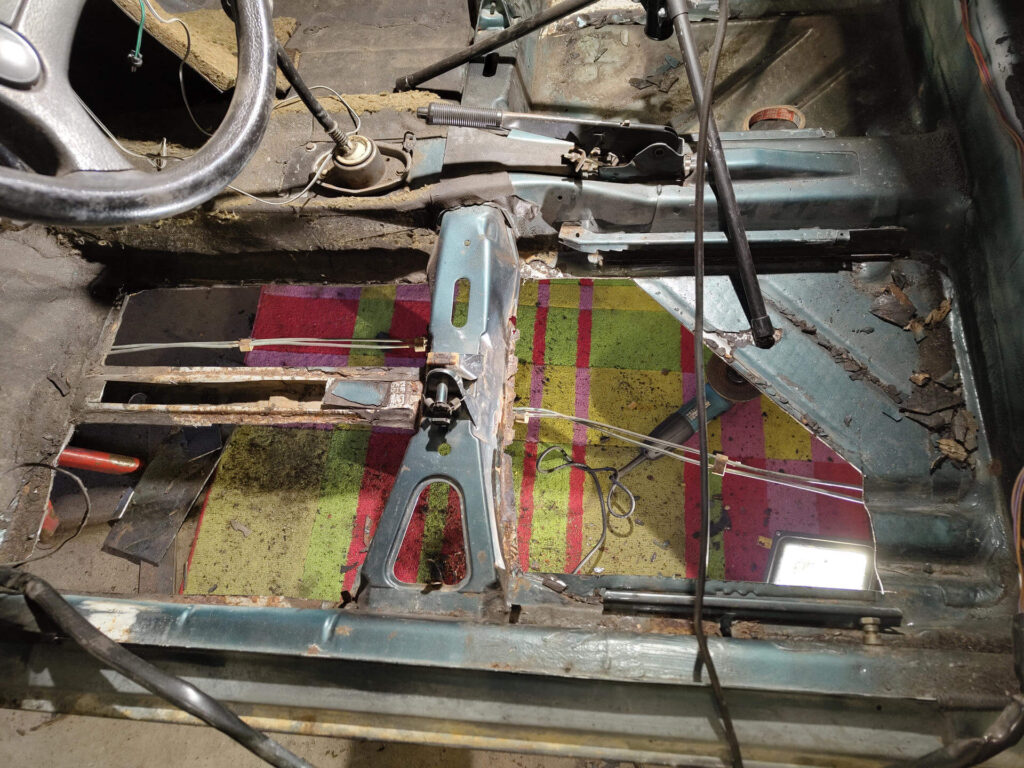

The first major task was tackling the corrosion head-on. That meant stripping out the entire interior to gain full access to the floor pan and prepare for some serious cutting and welding. This critical step ensures a solid foundation for the entire build.

Soon, large sections of the rusted floor were carefully cut away, making way for fresh, solid metal. This precision work is crucial for maintaining the structural integrity of the chassis.

As the old, rusted metal was removed, the commitment to building a new, robust foundation grew stronger. Each piece of new metal brought the car closer to its original strength and longevity.

New, perfectly formed floor sections were meticulously prepped and aligned, ready to be welded into place. This process is key to ensuring a flawless and durable finish for decades to come.

A critical part of ensuring longevity was blasting and treating all the smaller, rusty components from the undercarriage. These parts were meticulously sandblasted back to bare metal.

All previously rusty parts sandblasted and painted with black hammerite (Here you can see the transformation of various components: from rusty and worn to perfectly smooth and protected with a durable black hammerite finish, ensuring longevity and a clean look.

Finally, after painstaking work, the new floor sections were welded into place, creating a solid, factory-fresh foundation that will serve as the backbone of this iconic car.

Suspension & Rolling Stock Evolution: Laying Down the Style

A car’s stance and wheels truly define its character and presence. For this Mk1 GTI, I opted for a set of classic 15″ OZ Vega wheels. They arrived in fairly rough shape, but their timeless design and undeniable potential made them the perfect choice for this build.

The initial condition of the wheels was a testament to their age, but a vision of polished lips and perfectly restored centers motivated the transformation ahead.

A quick test fit confirmed they were the perfect choice for the Mk1’s lines, even with the car still on jack stands. The garage atmosphere, with my sister’s early white Mk1 cab on the lift, always makes for a great backdrop for these moments.

To get the ride height and handling just right, a set of D2 Coilovers were brought in – a crucial upgrade for a sharp and responsive driving experience. These will allow precise adjustments for both comfort and performance.

The D2 Coilovers represent a significant step towards modernizing the handling of this classic. Their adjustability will be key to achieving the perfect stance and dynamic performance.

he finishing touches on the wheels included finding a set of rare “waffle” center caps, giving them that authentic, period-correct look that truly completes their classic appeal.

Before they could truly shine, the original rusty rear axle also needed a full refresh, mirroring the meticulous work done on the rest of the underbody components. Its transformation was crucial for both safety and aesthetics.

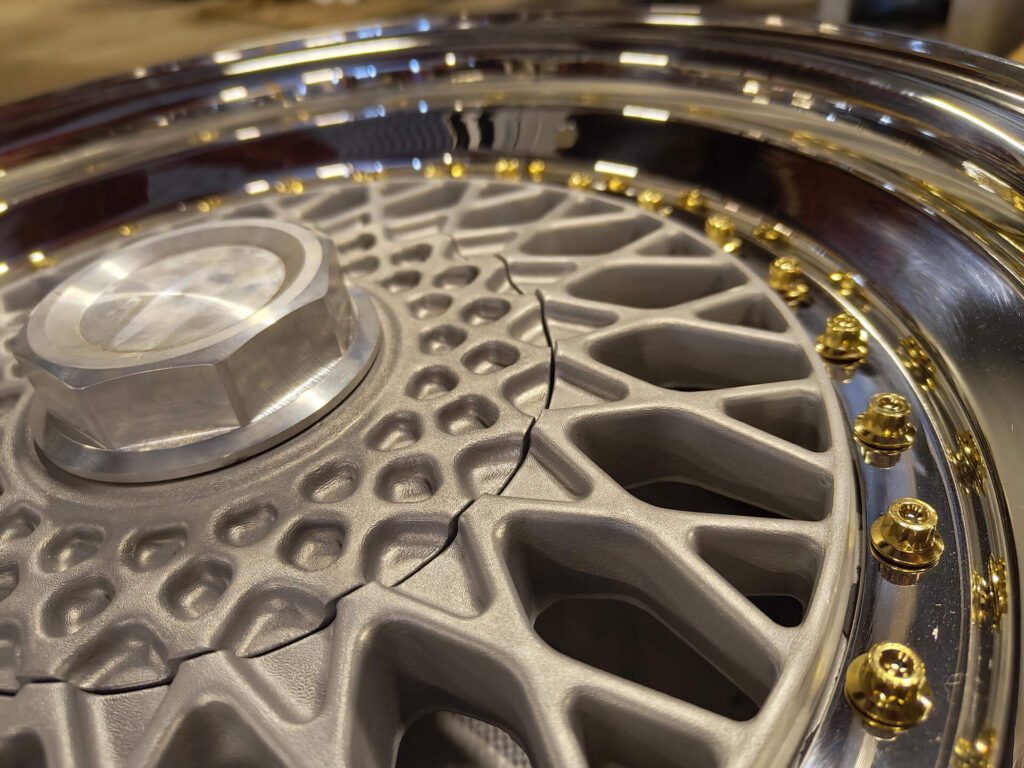

The wheel restoration itself was a meticulous process of disassembly, cleaning, and preparing the components. Instead of traditional polishing, we took the easier (but certainly more expensive!) route by acquiring a brand new set of Radinox lips, ensuring a flawless and perfectly true foundation. The centers were meticulously glass-blasted down to bare aluminum, ready for their fresh finish.

The culmination of this detailed wheel work is stunning. With the new Radinox lips providing a perfect mirror finish and the freshly prepared centers, the custom billet aluminum center caps are the final touch, adding a unique and high-quality detail that truly sets them apart and reflects the commitment to perfection in this build.

Looking Ahead: The Road to Rebirth

With the initial chassis repairs well underway, the extensive rust work progressing towards a full underbody refresh, and the suspension and rolling stock taking shape, the Golf Mk1 GTI is well on its way to its new life. The next big steps involve completing the underbody preparation and reassembly, followed by the engine – a planned light refresh and tune of the 1.8L K-Jetronic to reach around 120-125hp, ensuring that classic GTI punch.

Following that, a full respray in its original Lhasa Green Metallic (LA6V) will bring the exterior back to life, looking better than new. This build is a labor of love, a testament to preserving a classic while adding subtle, high-quality modifications.

Stay tuned to Low Standard Society, because the journey of this ’83 GTI is far from over, and you won’t want to miss the next chapter of its transformation!

[…] Check out the full story and all the progress photos on the Projects page: Here […]